Prior to the advent of motorcars rural inhabitant relied very heavily on transport by means of gigs and coaches. Next to the horses wheels were the most important element of this mode of transport.

Wheelwrights are now an almost extinct breed but for a number of years in the last few centuries wheel making was an important and thriving industry in the district.

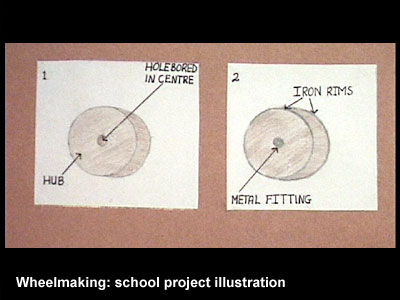

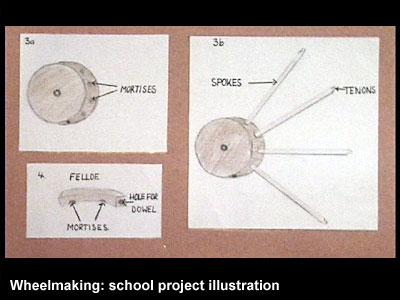

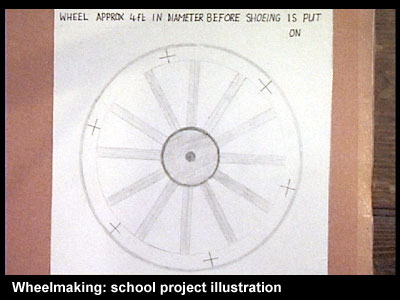

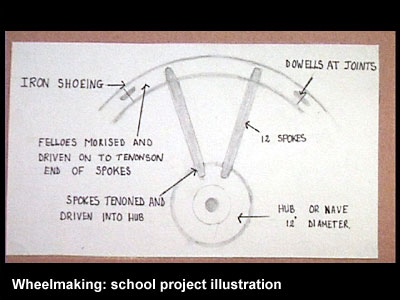

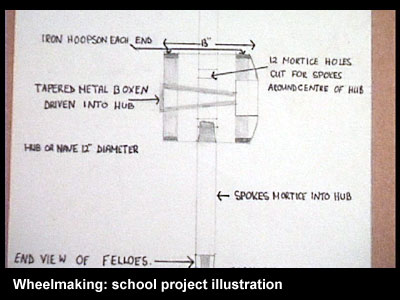

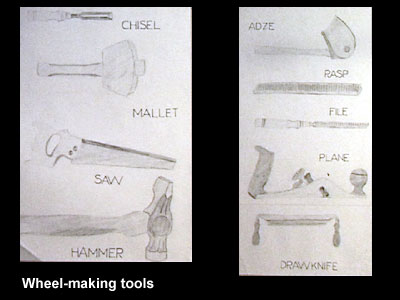

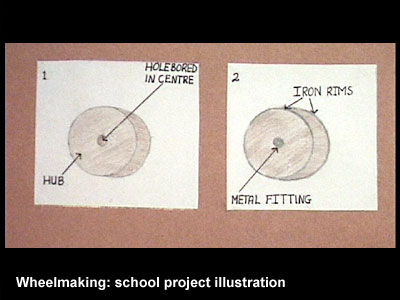

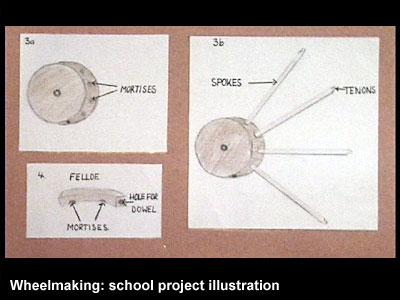

To make a wheel a hub was carved from elm wood and a hole bored through the centre. A metal fitting was placed through this hole to act as a socket for the axle. The blacksmith would strengthen the circumference of the hub by placing metal strips around it. Twelve sockets were cut at intervals around the circumference holding twelve spokes with a tenon at one end and the other driven into the mortises.

Six sections of ash wood would be cut to manufacture the rim. These sections, called felloes, each had two mortises carved onto the underside and these were driven into the tenons of the two spokes. The felloes were then doweled together. The wheel would then be trimmed and dressed ready to be fitted to the carriage.

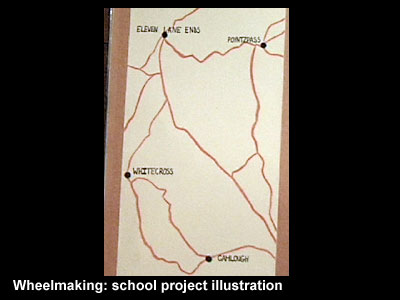

WHEELWRIGHTS FROM THE MARKETHILL AREA

| Willie-John Geddis | Eleven Lane Ends | 1880-1920 |

| David Geddis | Eleven Lane Ends | 1900-1940 |

| John Waddell | Poyntzpass | 1930-1940's |

| Terence Toner | Whitecross | 1939-1970's |

| Mr.McKeown | Camlough | 1980's |

REFERENCES

Information derived from material courtesy of the History Department, Markethill High School.